RF Welding Solutions

Other Services:

- Mold Design and Fabrication

- Process Development

- Sample Runs for Evaluation

- Validation Support

Model No. | RF-Shuttle-S1 |

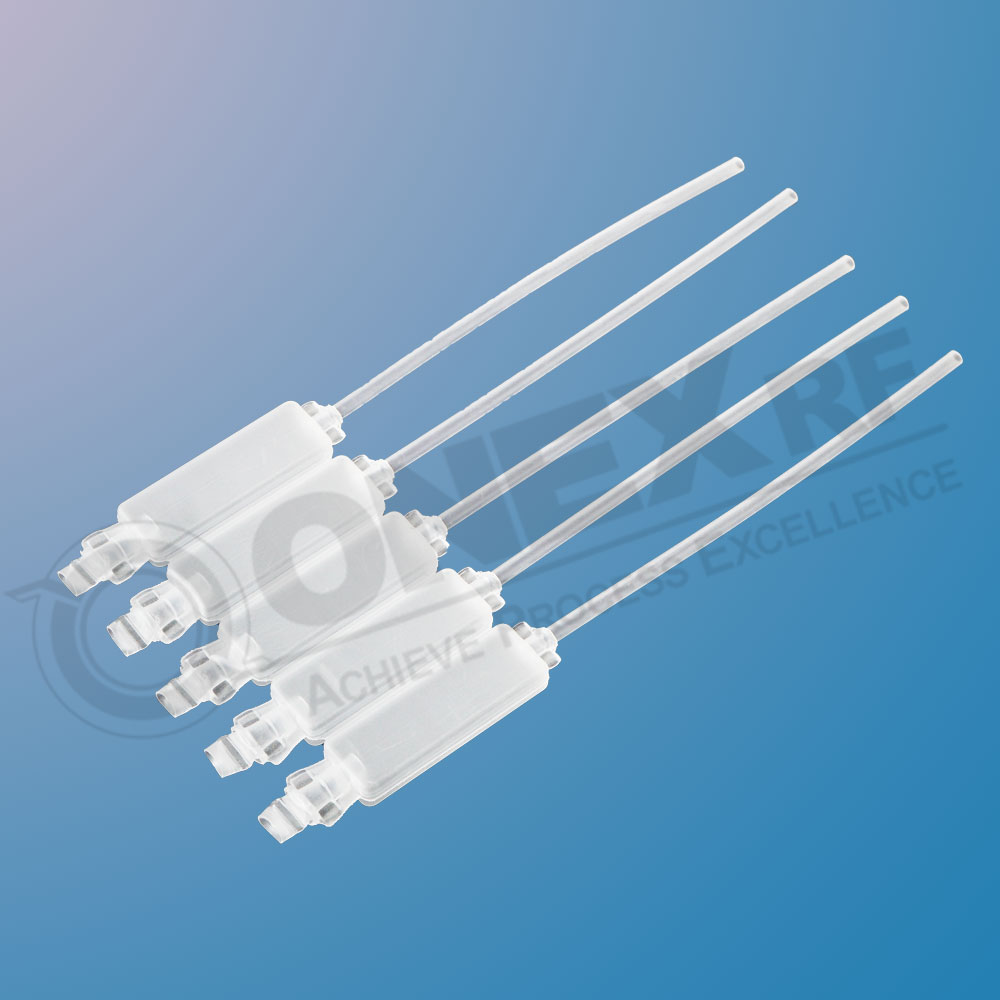

Applications | RF Sealing small medical sample pouches, ports on solution bags and air bladders |

RF Seal Area | 10" x 20" |

RF Generator | 2 - 4 kWatt Hybrid RF Generator 27.12 MHz Frequency |

Control System | Allen Bradley PLC 12" Touch Screen PC HMI |

Utilities | 200-240VAC / 40A / 50-60Hz 80 psi / 5bar - Clean Dry Air (CDA) |

Footprint | 37" x 45" / 94cm x 114cm - RF Welder 24" x 32" / 61cmx 81cm - RF Generator |

Shipping Weight | 2000lb / 850kg |

Compliance | ISO 13485-1 / UL-508C, NFPA 79A / Safety CE Optional |

Validation Support | Documents available for IQ, DOE and Die FAI OQ at customer site per request |

Operating Environment | 65-95°F / 18-35°C 68% Max Humidity Non-Condensing Max 2000m elevation |

RF Seal Area

Key Benefit

RF Output Power

90% Reduction of RF Sealing Arcs & Die-Burns when using ONEX RF sealers.

Increased production yields due to process consistency and RF Seal integrity.

50% more power efficiency when RF sealing with Hybrid RF Generator technology.

ONEX RF SEALERS ARE EASY TO SETUP AND VALIDATE.

BE THE MASTER IN RF WELDING BY USING THE ONEX RF TECHNOLOGY.

Customer Requirements:

The customer was looking for a small footprint RF Welder with a heat sealing option for the R&D department.

ONEX RF Solution:

We provided a small RF welder and added the heat sealing option to the upper platen to be able to seal polar and non-polar material products.

Customer Requirement:

Customer was a R&D firm and had already designed the pouch but could not find a company that would help them with samples and later they would purchase the system.

ONEX RF Solution:

We used our existing small shuttle RF welder and manufactured the dies to provide samples when they were improving the design. After 100 samples customers purchased the the RF sealer and we helped them with validation.

We provided the following systems:

Customer Requirement:

Customer was looking to manufacture Tourniquet cuffs many different sizes.

ONEX RF Solution:

We provided the complete RF welding line with three different RF welders for each process.

For quick response, please provide details of your product, process needs, and full contact information.

For application related questions, you can always reach us by phone at +1(626)358-6639.

We offer excellent service:

We look forward to working with you soon.

EXPECT ONLY EXCELLENCE

ONEX RF Inc. is dedicated to giving you excellent service with quality results. Expect only excellence.

Copyright © 2020 ONEX RF . All rights reserved.Trademarks, including but not limited to ONEX RF Design are the trademarks or registered trademarks of ONEX RF and used under license by ONEX RF Based on mixed usage scenario.Terms of Use | Privacy Policy