Catheter Tipping Solutions

Other Services:

- Mold Design and Fabrication

- Process Development

- Sample Runs for Evaluation

- Validation Support

Servo Precision catheter tip forming machine for R&D and Manufacturing use.

The Servo Tipper PRO comes with speed control to match the material flow, insertion force control to prevent over-insertion, and gripping pressure control to adjust clamp to tube hardness. It's the perfect choice to create short-tip catheters, sheaths, and over 3" long tapered tip introducers. The Servo Model is fully loaded and can be used in almost all catheter forming, flaring, and bonding applications.

Model No. | Servo Tipper PRO |

Applications | Distal End Forming Proximal End Flaring Bonding |

Product Size | 2Fr-38Fr 0.01" - 4.00" |

RF Generator | 30-300 watts 6.78 MHz Frequency |

Control System | Allen Bradley PLC Kinetix 350 Servo Drive 7" Touch Screen PC HMI |

Servo Slide Controls | 2097-V31PR0-LM AB Servo Drive MPL-A1530 AB Servo Motor LX3010-S1-N1-200 / 5" Stroke Slide |

Left Side Slide | 1" Stroke Guided Cylinder Flex-Gripper Mounting Bracket |

Utilities | 100-240VAC / 15A /50-60Hz 80psi / 5bar Clean Dry Air (CDA) |

Small Footprint | 14" x 24" / 356mm x 610mm |

Shipping Weight | 69lb / 31kg |

Compliance | CE Marked UL per request |

Validation Support | Documents available for IQ, FAI, DOE OQ at customer site per request |

Operating Environment | 65-95°F / 18-35°C 68% Max Humidity Non-Condensing Max 2000m elevation |

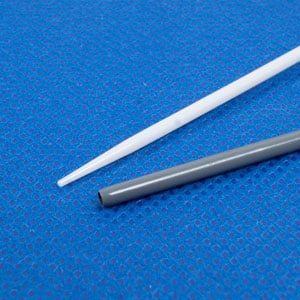

French Sizes

Tip Lengths

Material Temps. (Tg)

Innovative, Results-Oriented Team Environment

Focused on problem-solving and timely execution of customer requirements

Delivering solutions through new technologies backed by essential customer training

ONEX RF TIPPERS ARE EASY TO SETUP AND VALIDATE.

BE THE MASTER IN CATHETER TIPPING BY USING THE ONEX RF TECHNOLOGY.

Customer Requirement:

Customer had tight tolerances and the contract manufacturer could not control the process to achieve a consistent wall thickness and shape. They asked us to develop a consistent forming process.

ONEX RF Solution:

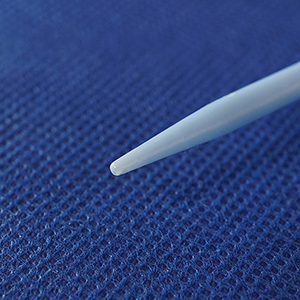

We analyzed the material properties and created a special funnel shaped die and wound several types of coils so we could balance the heating and even flow of the material. It was a matter of balancing the heat and controlling the material pressure to create the perfect tip every cycle.

We used the following system:

Customer Benefit:

Customer got a consistent process and was able to increase the throughput from 800-1000/day and reduce scrap 25%.

Customer Requirement:

The Sheath distal end tips were cracking and splitting open after the forming process. They used an older catheter tipping system and did not have much control.

ONEX RF Solution:

We analyzed the materials and identified some ways to improve the process. We built a sample die and did full process development. Customer liked the results and purchased several systems replacing the old ones.

We Offered the following:

Customer Requirement:

Customer had purchased a tip forming system and could not validate the process due to inconsistencies and flash issues every time they changed the setup.

ONEX RF Solution:

We reviewed the materials and current setup and offered to manufacture new dies and perform process development for three different catheters. Customer liked the results and purchased one system at first. After the successful validation and production, we received several new system orders.

We offered the following solutions.

For quick response, please provide details of your product, process needs, and full contact information.

For application related questions, you can always reach us by phone at +1(626)358-6639.

We offer excellent service:

We look forward to working with you soon.

EXPECT ONLY EXCELLENCE

ONEX RF Inc. is dedicated to giving you excellent service with quality results. Expect only excellence.

Copyright © 2020 ONEX RF . All rights reserved.Trademarks, including but not limited to ONEX RF Design are the trademarks or registered trademarks of ONEX RF and used under license by ONEX RF Based on mixed usage scenario.Terms of Use | Privacy Policy