Catheter Tipping Solutions

Other Services:

- Mold Design and Fabrication

- Process Development

- Sample Runs for Evaluation

- Validation Support

Model No. | STB-807-LX1 |

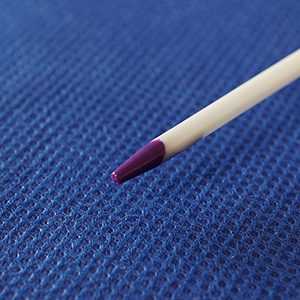

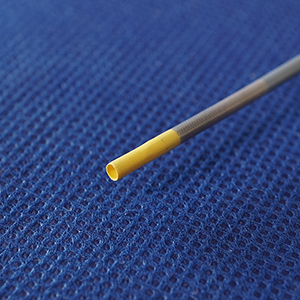

Applications | Distal End Soft Tip Bonding and Forming Proximal End Flaring |

Product Size | 2.5Fr-34Fr 0.1" - 2.5" |

RF Generator | 30-300 watts 6.78MHz Frequency |

Control System | Allen Bradley PLC 7" Touch Screen PC HMI |

Utilities | 100-240VAC / 15A /50-60Hz 80psi / 5bar Clean Dry Air (CDA) |

Small Footprint | 14" x 24" / 356mm x 610mm |

Shipping Weight | 69lb / 31kg |

Compliance | CE Marked UL per request |

Validation Support | Documents available for IQ, FAI, DOE OQ at customer site per request |

Operating Environment | 65-95°F / 18-35°C 68% Max Humidity Non-Condensing Max 2000m elevation |

French Sizes

Tip Lengths

Material Temps. (Tg)

Innovative, Results-Oriented Team Environment

Focused on problem-solving and timely execution of customer requirements

Delivering solution through new technologies backed by essential customer training

ONEX RF TIPPERS ARE EASY TO SETUP AND VALIDATE.

BE THE MASTER IN CATHETER TIPPING BY USING THE ONEX RF TECHNOLOGY.

Customer Requirement:

Customer had purchased a tip forming system and dies but could not validate the process. After six months of back and forth, they were not able to resolve the inconsistency and bond issues. We met the customer at the Expo and invited them to ONEX and demonstrated our capabilities. It did not take long to hear back from them. They told us that if we can develop a die and do a POP, they will buy the system. This was after they had already purchased two other systems and the project was late by 3 months.

ONEX RF Solution:

We requested the samples and drawings and built the 1st die in 2 weeks. After several days, we were producing good samples. After reviewing the initial samples, we worked with them to modify the design and manufactured another set of dies and mandrels. We gave our customer the perfect process they were not able to achieve for months.

We then created the DOE IQ documents and helped the customer with the installation.

Customer Issue:

The current system was old and required long hours to change the setup and tune the coil to get good results. The setup required water cooling and would leak from time to time, causing contamination issues.

Our Solution:

One beautiful morning our customer contacted us with intense pressure in her voice and said we need a system capable of making the parts in one month, can you help? In LESS than 2 weeks we were able to make the die and samples for review. Customer liked the results and purchased a system with a promise that we would do the DOE run samples and they would perform all the inspection and documentation.

We then created the DOE IQ documents and helped the customer with the installation.

For quick response, please provide details of your product, process needs, and full contact information.

For application related questions, you can always reach us by phone at +1(626)358-6639.

We offer excellent service:

We look forward to working with you soon.

EXPECT ONLY EXCELLENCE

ONEX RF Inc. is dedicated to giving you excellent service with quality results. Expect only excellence.

Copyright © 2020 ONEX RF . All rights reserved.Trademarks, including but not limited to ONEX RF Design are the trademarks or registered trademarks of ONEX RF and used under license by ONEX RF Based on mixed usage scenario.Terms of Use | Privacy Policy