ONEX RF Hybrid Generators - Consistency | Efficiency | Reliability | Versatility and Value

The RF Welding Machine Challenge

When sealing complex medical pouches, blood bags, urinary bags and similar products, high consistency and repeatability is required. However, this isn’t the case with most RF sealing systems using standard oscillator tube RF generators. Their low frequency and harmonics don’t allow efficient power coupling; tending to dissipate power, only transferring 30-70% of total power to the load (sealing dies). Aside from the basic inefficiency of the equipment, users also experience excessive down time mainly due to arcs and constant tuning of parameters and system components due to product and die changeovers on the same equipment.

ONEX RF Automation, Duarte, CA, specializes in the design and manufacture of manual and automated RF sealing systems for medical device, automotive and other manufacturing industries. Known for its focused solutions, ONEX RF looks outside the box to develop innovative and sound solutions for process challenges such as this one.

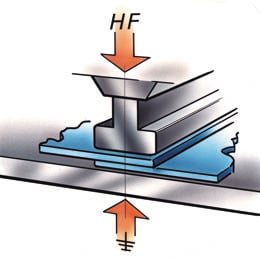

Onik Bogosyan, president of ONEX RF Automation, explains that to improve RF sealing system efficiency, coupling methods needed a technology upgrade. “Instead of typical loading to the heat source, (which constantly created arcs due to the sensitive product nature) we looked at a unique patented solution that uses solid state generator and direct coupling technology. This is similar to high end amplifier tuning as used to obtain maximum audio wattage for quality sound,” he says. “By direct coupling we were sure we would be able to transfer our amplified signal to the source with minimum loss in transaction and precisely control the power at the load in two sealing cycles.”

Onik Bogosyan, president of ONEX RF Automation, explains that to improve RF sealing system efficiency, coupling methods needed a technology upgrade. “Instead of typical loading to the heat source, (which constantly created arcs due to the sensitive product nature) we looked at a unique patented solution that uses solid state generator and direct coupling technology. This is similar to high end amplifier tuning as used to obtain maximum audio wattage for quality sound,” he says. “By direct coupling we were sure we would be able to transfer our amplified signal to the source with minimum loss in transaction and precisely control the power at the load in two sealing cycles.”

The concept of direct coupling allows the RF generator to transfer power direct to the load and with the servo controlled Auto Tuner system monitor the reflective power and constantly adjust the load impedance to achieve above 92% efficiency. The system runs more efficiently and consistently, while sealing the product to achieve maximum desired quality. The goal was to consistently deliver a more reliable and controllable process.

RF Sealing Precision and Repeatability: Hybrid RF Sealing Technology by ONEX RF

ONEX RF turned to their expertise in hybrid technology. The hybrid technology immediately eliminated the arcing, down time, maintenance and operator safety issues. This in turn, eliminated the issue of quick RF power degradation, producing high quality seals with consistency and repeatability previously unknown in the RF welding industry.“The Hybrid RF generator provides a consistent 27.12MHz high frequency signal, which is efficiently tuned to the load (product being sealed) using auto tuner. In addition to consistency the generator power is set via analogue signal from a PLC/PC based control system” Bogosyan says. “The Hybrid RF generator and auto tuner provide consistent seal with minimal power loss. The analog signal allows the power to be set and maintained precisely throughout the seal cycle, and be quickly changed to perform a different seal cycle. Based on our experience the system uses 50% less power than RF welders based on oscillator tube technology.”

“We tested this technology on a complex application sealing a sensitive medical product,” he adds. “The material was 0.009” thick and required very precise power control to prevent arcing or over-melting, in addition to the shape and size of the product, it had a valve port and a very small 0.032” diameter tubing welded onto the pouch. Initially, we’d done power calculations based on tube style generator which came to 2.3KW power for the parameter seal and 800W to weld the tubing. But, when we tested the dies using a conventional RF generator, we could not control the power efficiently and saw process variations, arcing and material burn. When we switched to solid state technology, we were able to achieve excellent results from the first attempt and the system utilized 50% less power compared with Tube style generator.”

Bogosyan points out that having the output power controlled by an analog signal is essential for sealing medical bags with port seals.. “In other aplications where we sealed newly introduced materials we were able to control the RF power precisely and perform seals with less power resulting in a high quality seal without burns or arcs” he says.

The new ONEX RF Sealers come with Hybrid RF generators, manufatured in California, US. The Hybrid generators use crystal oscillator driver and vacuum tube amplifier, which provides the ability to produce 20 or 30KW power. ONEX RF systems come in various style and design, manual shuttle or rotary (RF-Shuttle and RF- Roto), besides the manual systems we manufacture fully automated Rf sealing systems RF-Galaxy inline automated platforms. ONEX RF sealers are easy to setup and control.

The hybrid generator technology is much more repeatable and precise to couple to complex material formulations that it allows our medical customers to flexibly design the products choosing whide range of materials without any limitations. “We have accomplished great seals with some materials that were virtually impossible to seal by traditional RF welders,” Bogosyan says. “Hybrid technology easily adapts to applications that couldn't be successfully done using other systems.”

Versatile RF Welders: Expanding RF Welding Markets with ONEX RF

ONEX RF systems are easy to operate and validate for all medical applications. ONEX RF sealers use strong mechanical platform and are perfect fit for medical and automotive applications. “Operators love using ONEX RF sealers after one day basic training,” he says. “Any manufacturer that needs the best RF welding/sealing system that uses half the energy and 90% less maintenance, will benefit using ONEX RF sealers. The ONEX RF Sealers are used in many industries including but not limited to automotive, packaging, military, office supply, recreational, flooring, air structure, pool liners and more.”ONEX RF-Hybrid generator technology allows customers to achieve results far beyond standard tube style RF sealing machines resulting in higher quality products and repeatable processes. “This is a revolutionary process that has been proven with many systems already in the field,” Bogosyan says.

-2.gif)

.png)

-1.png)