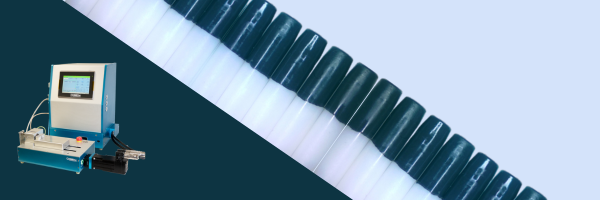

PEBAX is a versatile material often used in catheter construction—but when it comes to forming flares, its slightly sticky behavior can create challenges. In this post, we walk you through how we formed a clean, concentric flare on a 5Fr PEBAX tube using ONEX RF’s CTF-807-LX1 catheter tipping machine. You’ll find parameters, setup notes, key challenges, and insights that helped us achieve 95% success across 60 samples.

Material Overview

- Material: PEBAX

- Size: 5Fr

- Application: Flaring

- Behavior: Slightly sticky, prone to uneven flow without careful heat control.

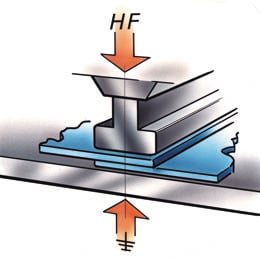

Tooling & Process Setup

- Die design: Flaring die with temperature feedback

- Mandrel: Not used

- Machine used: ONEX RF CTF-807-LX1

- Fixture details:

The tube was positioned deep onto the flaring die until it reached a hard stop. Custom grippers were used to hold the tube firmly in place without causing deformation. No mold release or die coating was needed, thanks to the optimized temperature control built into the tooling.

Forming Parameters

| Parameter | Value |

|---|---|

| Preheat Time | 5 seconds |

| Die Temperature | 135°C |

| Forming Time | 5 seconds |

| Insertion Depth | 0.5 inch |

| Cooling Time | 10 seconds |

| Notes |

Allow die to reach the set temperature and continue heating for a few seconds to evenly heat the die before insertion. |

Process Challenges & Lessons Learned

Initial challenges:

- The flare was forming unevenly, with one side flaring longer than the other.

Solutions that worked:

- Switching to a much longer coil created a wider, more uniform heat zone. This ensured the entire flare area and pre-loading section reached a consistent temperature before forming began so that the material was already softened before flaring.

Final Results

- Tip shape consistency: 95% of samples were within specification across a 60-sample run

- Visual quality: No voids, concentric flare shape, and even tip length

Insights for Engineers

- Heat zone control is everything. A longer coil distributes heat more uniformly, reducing risk of asymmetric tip geometry.

- No mandrel needed. For this size and shape, proper die positioning and custom grippers provided enough support.

- Preheating thoroughly prevents defects. Fully and evenly heating the die before forming helps avoid inconsistent softening and flow.

Related Resources

- View our CTF-807-LX1 machine. Interested? Request your quote now!

- We can design and manufacture your dies in 2-3 weeks

- Request a sample tip formed from your tubing

Need help flaring PEBAX or other materials?

ONEX RF specializes in precise, repeatable tip forming processes. If you’re dealing with uneven flares or material-specific challenges, reach out to ONEX RF and we’ll help you get production-ready

.png)

-2.gif)

-1.png)

.png)