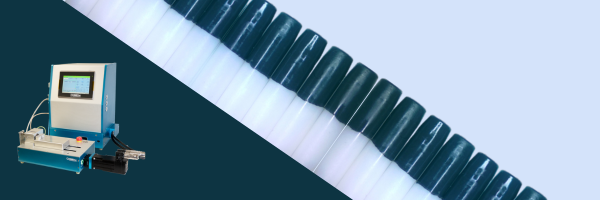

When forming catheter tips using PVC, success hinges on mastering heat control and material flow. In this post, we break down how we formed a 21Fr bullet nose tip from PVC using the ONEX RF CTF-807-LXS2—sharing key parameters, setup tips, and the process insights we learned along the way.

Material Overview

- Material: PVC

- Size: 21Fr

- Application: Bullet nose catheter tip

- Behavior: PVC flows forward very well under heat, but requires a carefully managed heat zone to maintain control and consistency.

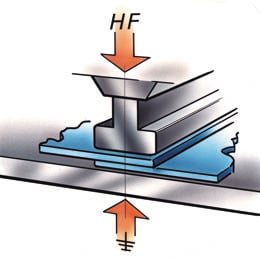

Tooling & Process Setup

- Die design: Closed-tip die for bullet nose shape

- Mandrel: Straight mandrel

- Machine used: ONEX RF CTF-807-LXS2

- Fixture details:

A positioning fixture was integrated into the mandrel setup. The tube was loaded onto the mandrel until it hit the backstop, ensuring consistent placement. The tube was then inserted deeply into the die until it bottomed out, allowing the material to collapse at the tip area while preserving the lumen just behind it.

Forming Parameters

| Parameter | Value |

|---|---|

| Preheat Time | 2 seconds |

| Die Temperature | 155°C |

| Forming Time | 7 seconds |

| Insertion Depth | 10 mm (beyond tip length) |

| Cooling Time | 7 seconds |

| Notes | Insert slowly (~1 mm/sec); coil heats only half the tip |

Process Challenges & Lessons Learned

Initial challenges:

- PVC was sticking to the die.

- Tip shapes were incomplete or inconsistently formed.

Solutions that worked:

- Mold release was applied to prevent sticking.

- The coil was designed to heat only the start of the taper, allowing the material to begin melting and flow forward as it contacted the die.

- Overinsertion was key. Inserting the tube deeper than the length of the bullet nose ensured that enough material flowed to form both the outer shape and fill the inside of the tip.

Final Results

- Tip shape consistency: 99% of samples met spec (60 samples tested)

- Visual quality: Fully formed tips with no voids or bubbles

Insights for Engineers

- Partial heating is powerful: Only heating the initial taper encourages controlled flow and reduces the risk of overheating or warping.

- Insertion depth matters: Overinserting ensures the material fills out the bullet nose profile completely.

- Coil placement is critical: Placing the coil at the beginning of the taper helps initiate controlled melt and forward material flow.

Related Resources

- Interested in the CTF-807-LXS2 machine? Request your quote now!

- See how material choice can affect catheter tipping outcomes

- Request a sample tip formed from your tubing

Need help forming PVC or a similar material?

We’ve helped customers bring PVC tipping into production faster with robust, repeatable processes. If you’re struggling with tip shape, forming consistency, or lead times—reach out to ONEX RF and we’ll help you dial it in.

-1.png)

-2.gif)

.png)

.png)