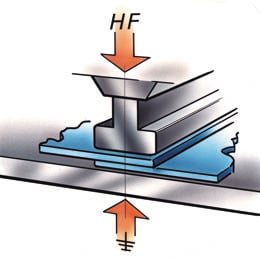

PVC is a widely used catheter material thanks to its ease of processing, flexibility, and cost-effectiveness. When forming angled tip radii, precision in tooling design and process control is critical to achieving smooth inner and outer radii without compromising lumen integrity. This case study details the exact RF tipping setup, parameters, and lessons learned when forming a 14Fr PVC catheter tip on an ONEX RF tipping machine.

Material Overview

- Material Name: PVC

- Typical Catheter Applications: Endotracheal tubes with inner and outer radius

- Size Tested: 14Fr

- General Behavior During RF Heating:

PVC is easy to work with and forms both inner and outer radii cleanly when parameters are precisely controlled.

Tooling & Process Setup

- Die Design Used: Stainless steel die with a precision-angled cavity.

- Mandrel Type: Integrated mandrel as part of the die.

- Machine Used: ONEX RF CTF-807-LX2 RF tipping system.

- Fixture Setup Notes:

Tube must be inserted with correct orientation, as the tip is pre-cut at an angle before the tipping process begins.

Forming Parameters

| Parameter | Value | Notes |

|---|---|---|

| Preheat Time | 1 second | Quick preheat to stabilize die temperature |

| Die Temperature | 150°C | Ideal for PVC forming without material degradation |

| Forming Time | 1 second | Short dwell to prevent material flow into the lumen |

| Insertion Depth | 1 mm | Forms only the tip radius on inner and outer edges |

| Cooling Time | 5 seconds | Ensures tip retains shape without distortion |

| Total Cycle Time | 8 seconds* | *Product Load-unload time is not included |

Process Challenges & Lessons Learned

Initial challenges:

- Material flowed backwards past the inner mandrel, closing the lumen opening. The coil position was too far from the tip and was heating the shaft unnecessarily. The correct cutting angle without a flash is also essential in the forming process, as even a small imperfection can affect both the functionality and quality of the final product. Achieving this consistently demands a combination of the right tooling, heat application, and process control.

Solutions that worked:

- Reduced insertion depth to 1 mm.

- Reduced form time to 1 second to limit heating only to the tip radius area.

- Moved coil position all the way to the tip so it only heats the tip portion.

Tooling or Setup Tweaks:

- Redesigned the die and remanufactured it within 1 week, enabling testing and delivery of customer-approved samples on schedule.

Final Results

- Tip Shape Consistency: 100% of samples met dimensional requirements.

- Visual Quality: Fully formed inner and outer radius with no voids or sharp edges.

Insights for Engineers

- Accurate die design, based on well-defined requirements, is essential for PVC angled tip radius forming.

- Short insertion and form times are key to preventing lumen blockage while achieving a smooth tip finish.

Related Resources

- View our CTF-807-LX2 machine (1-2 weeks lead time)

- Read how we flared a 5Fr PEBAX tip

- We can design and manufacture your dies in 2-3 weeks

- Request a sample tip formed from your tubing (4 weeks lead time)

Need help tipping PVC or other materials?

ONEX RF specializes in precise, repeatable tip forming processes. If you’re dealing with uneven flares or material-specific challenges, reach out to ONEX RF and we’ll help you get production-ready

.png)

-2.gif)

.png)

-1.png)