At ONEX RF, we recently developed a process to taper and bond 9Fr PEBAX catheter sheaths using RF —a material known for its flowability and need for precise temperature control. In this case study, we share the tooling setup we used for our CTF-807-LXS1 RF tipping system, process parameters, and lessons learned that helped us achieve strong bonds and flash-free, consistent tips. This breakdown is designed to give engineers practical insights into working with PEBAX and highlight how servo-controlled insertion and closed-loop temperature feedback can make all the difference in catheter tip forming.

Material Overview

- Material Name: PEBAX

- Typical Catheter Applications: Taper forming and bonding for medical device manufacturing

- Size Tested: 9Fr

- General Behavior During RF Heating: PEBAX flows easily when heated but requires precise temperature control to achieve strong bonds with the catheter shaft.

Tooling & Process Setup

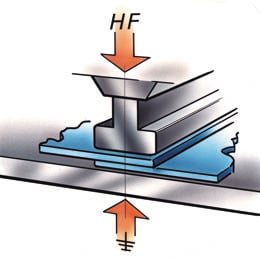

- Die Design Used: Precision tapered die with shutoff to control material flow and prevent flash.

- Mandrel Type: Straight mandrel with tight concentricity tolerance.

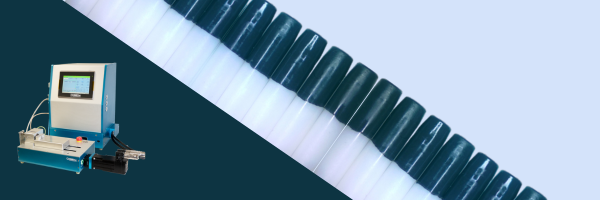

- Machine Used: ONEX RF CTF-807-LXS1 RF tipping system.

- Fixture Setup Notes:

- Spring-loaded mandrel to create an effective shutoff at the end of the die cavity.

- Closed-loop temperature feedback for consistent die temperature.

Forming Parameters

| Parameter | Value | Notes |

|---|---|---|

| Preheat Time | 2 seconds | Stabilizes die temperature before forming. |

| Die Temperature | 200°C |

High enough for full blending of tip and shaft material. |

| Forming Time | 2 second | Short dwell prevents excessive flow. |

| Insertion Depth | 25 mm | Matches desired taper length. |

| Cooling Time | 10 seconds | Ensures dimensional stability. |

| Total Cycle Time | 14 seconds* | *Product Load-unload time is not included |

| Insertion Speed | 6 mm/sec | Achieved using servo-controlled slide. |

Process Challenges & Lessons Learned

Initial challenges:

- Low temperatures formed the tip but produced weak bonds.

- Increasing temperature improved bonding but caused flash as molten material leaked past the shutoff.

Solutions that worked:

- Reducing heat exposure time while rapidly inserting the tube (6mm/sec)

Tooling or Setup Tweaks:

- Servo-controlled insertion for precise, high-speed forming (not achievable with pneumatic slides).

- Closed-loop temperature control for consistent results.

Final Results

- Tip Shape Consistency: 98% of samples met dimensional specifications.

- Visual Quality: Fully formed taper with no flash and no sticking.

- Bond Strength: Passed tensile strength requirement of 16 N.

.png?width=369&height=461&name=9Fr%20Tapered%20Tip%20From%20PEBAX%20(1).png)

Insights for Engineers

- Bonding PEBAX requires high die temperatures for full blending with the catheter shaft.

- Fast, servo-controlled insertion is critical to achieving flash-free tips.

- Slow insertion increases the risk of material sticking.

Related Resources

- Get your CTF-807-LXS1 tipping machine now! (1-2 weeks lead time)

- Read how we tipped PVC beveled endotracheal tube

- We can design and manufacture your dies in 2-3 weeks

- Request a sample tip formed from your tubing (4 weeks lead time)

Need help tipping PEBAX or other materials?

ONEX RF specializes in precise, repeatable tip forming processes. If you want to make your process more efficient with less steps, reach out to ONEX RF and we’ll help you get production-ready

-2.gif)

.png)

-1.png)

.png)