When planning a catheter development or production program, real production output is often underestimated. Many teams focus on advertised cycle time or early feasibility results, only to discover later that their actual daily throughput falls short of program needs.

In practice, production output is not defined by how fast a machine can cycle. It is defined by how many validated, in-spec catheter tips the entire process can consistently produce under real manufacturing conditions—accounting for tooling performance, cooling time, operator handling, yield, changeovers, and equipment downtime.

Understanding true output early helps prevent delays, re-validation, missed builds, and unexpected capital expenses.

The Most Common Capacity Planning Mistake

The most common mistake is sizing equipment based on best-case cycle time instead of validated throughput under production conditions.

This typically includes:

- Assuming near-perfect yield

- Underestimining operator touch time

- Planning for only one die or mandrel

- Not accounting for downtime or maintenance

These assumptions may appear valid during early trials. However, once validation standards tighten and production begins, the gap between theoretical speed and actual output becomes clear.

Why Output Gaps Causes Timeline Delays

Production shortfalls are often discovered too late—after validation protocols, regulatory submissions, and launch timelines are already defined.

Common contributors include:

- Longer cycle times once quality standards are enforced

- Additional tooling required mid-validation

- Unaccounted for post-tipping process

- Unplanned downtime for die adjustments or maintenance

Even small output gaps compound quickly over weeks of builds, leading to missed milestones and delayed submissions.

Key Factors That Control Throughput

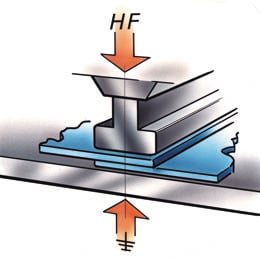

Cycle and Cooling Time

Cycle time includes heating, forming, stabilization, and cooling. Cooling is frequently underestimated, especially for thicker walls and longer tips.

Operator Interaction

Manual loading, inspection, and adjustments affect throughput. At volume, even a few extra seconds per part add up quickly.

Changeovers

Switching sizes reduces available production time. Programs with multiple SKUs require tooling strategies that minimize changeover time and protect uptime.

Downtime and Stability

Real-world production includes:

- Die wear

- Parameter fine-tuning

- Preventative maintenance

Ignoring downtime during planning leads to unrealistic daily output assumptions.

How Materials and Geometry Impact Capacity

.png?width=600&height=200&name=email%20footers%20(2).png)

Material choice impacts heating and cooling behavior:

-

PVC allows shorter cycles

-

PEBAX benefits from controlled motion

-

PU, PTFE, PEEK require tighter control

Tip geometry also plays a major role:

-

Simple tips → Faster, more stable cycles

-

Long or complex tapers → Longer heating and cooling phases

As complexity increases, validated output naturally decreases unless equipment and tooling are sized accordingly.

Planning Equipment for Real-World Production

Engineers should evaluate production output during early design and feasibility—not after validation begins.

Early planning prevents:

- Late-stage tooling additions

- Re-validation events

- Unexpected machine upgrades

- Launch delays

At ONEX RF, we help customers evaluate true production throughput by:

- Analyzing realistic cycle times with production parameters and tooling

- Evaluating tooling scalability (1-up, 2-up, 4-up configurations)

- Matching machine architecture to material and geometry

- Designing validation-ready, stable processes

- Planning redundancy to reduce downtime risk

This allows customers to move from feasibility to validation and production with fewer surprises.

The Bottom Line

Machine speed does not equal production output.

Real throughput is defined by how many validated, sellable catheter tips can be produced per shift—under real operating conditions.

By planning for yield, tooling, materials, geometry, operator interaction, and downtime from the beginning, teams can protect their timelines and reduce program risk.

If you are sizing a new tipping process or scaling production, ONEX RF can help you evaluate true production output before it impacts your launch schedule.

-2.gif)

.png)

-1.png)

.png)