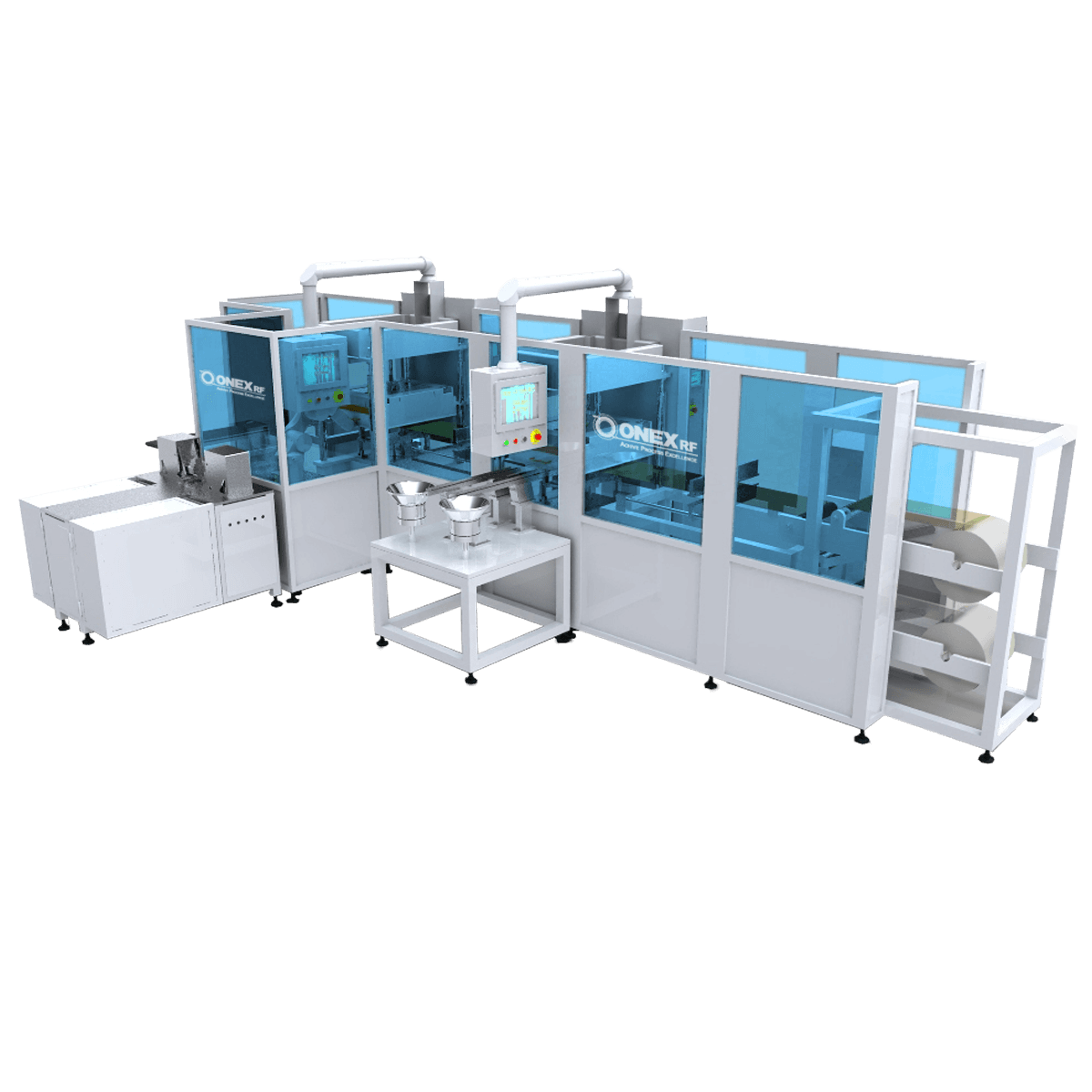

Zero-Die-Damage?

When an arc is detected, the ONEX RF welder can stop the RF energy faster than any RF welder in the industry. It saves you downtime & die repair or replacement costs. It's been proven with many systems in the field for over 10 years.

Unique Arc-Less Technology

- Stop Arc at Light-Speed

- Clean the die surface

- Start another cycle

- No repair or replace required

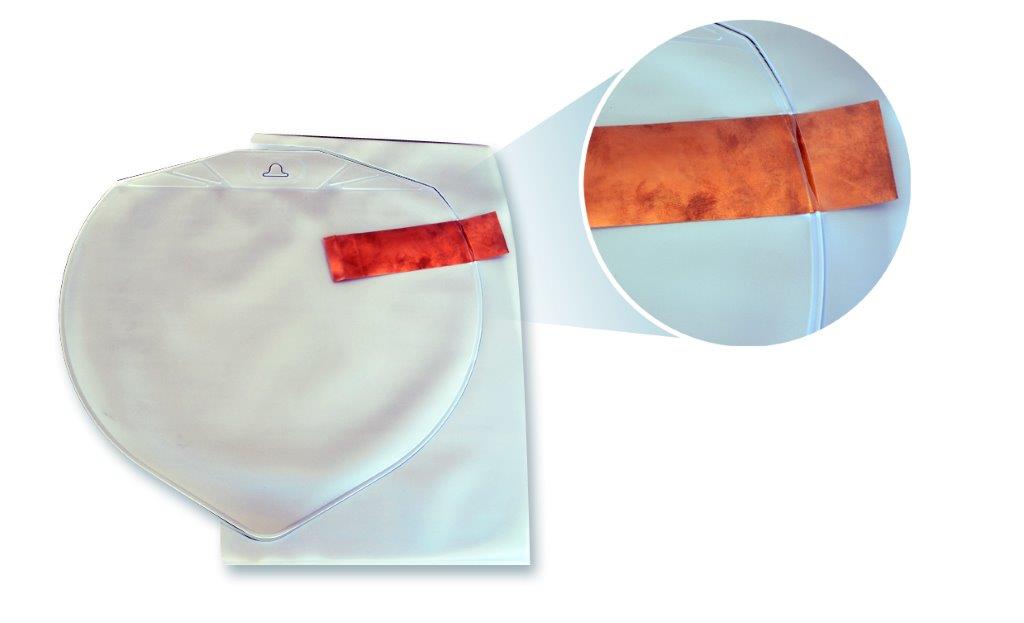

Don't try this on your welder.

For customer demonstration, we placed a copper foil between the film layers to RF seal a sample bag.

All RF Welders come with an Arc shut-down circuit. Some require adjustment when RF power is adjusted and some don't. We know for fact there are many situations where the RF sealing process will produce arcs, causing material burns, die damage, or even a fire. The RF sealing arcs can be caused due to the environment, product shape or design, or foreign particles on the film layers. The question comes down to how fast can your RF welder detect the arc and stop the RF power not to damage or burn the tooling.

ONEX RF Welders can detect the Arc faster than PLC can detect it. Imagine how fast we can stop the Arc.