- RF Welders and RF Heat sealing Machines

- +1-626-358-6639

- results@onexrf.com

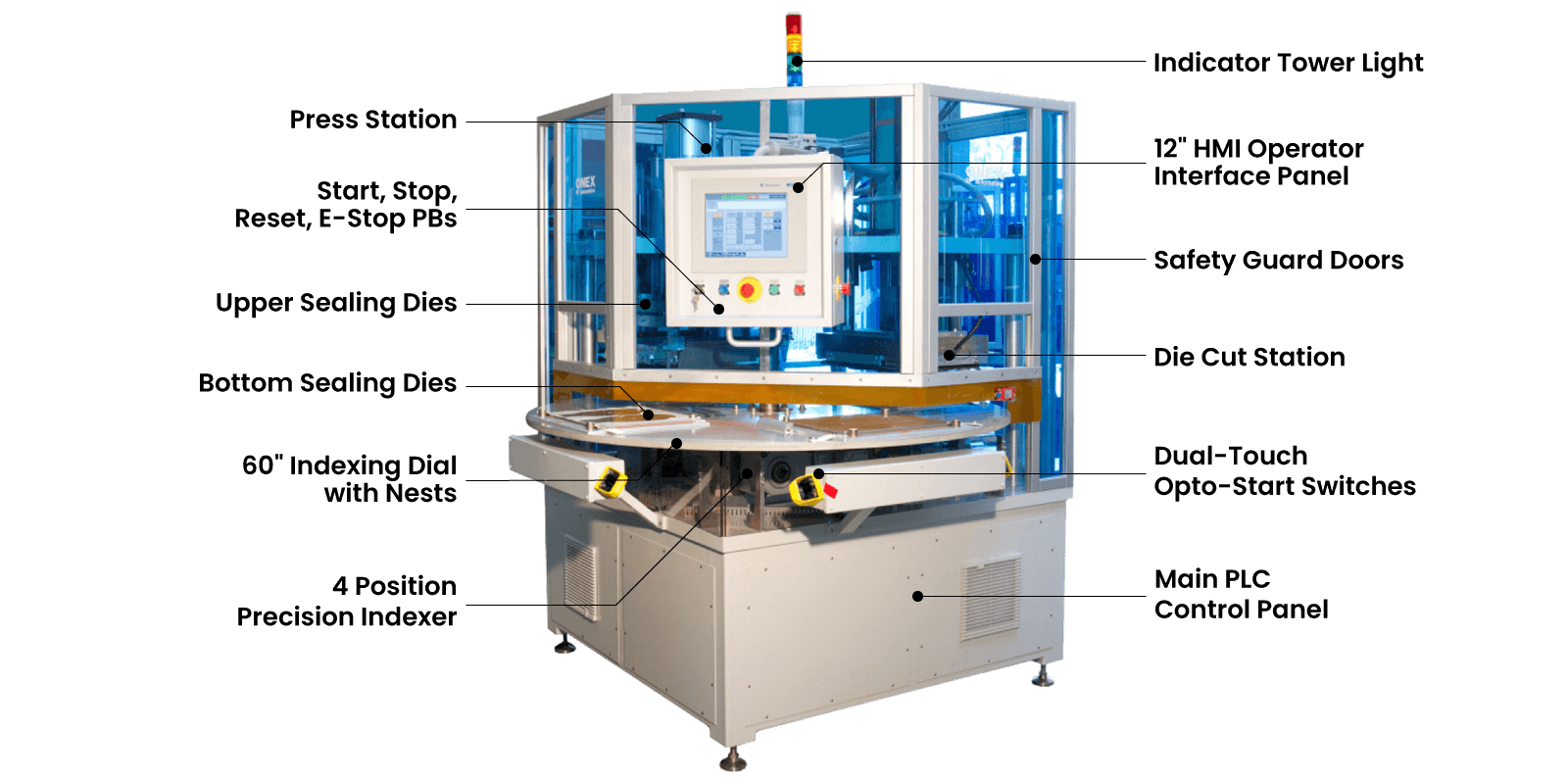

Model Number | HSDC-Roto-X4-D60-15x20 |

Heat Seal Area | 15 x 20" / 380 mm x 510 mm |

Heat Sealing Press Force | 1500 lb / 6672 Newtons (N) with single cylinder at 80-psi |

Heat Sealer Press Stroke | 4" / 100 mm during normal operation - 8" / 200 mm for maintenance |

Heat Seal Max Temperature | 450°C |

Die-Cut Area | 15 x 20" / 380 mm x 510 mm |

Die-Cut Station Press Force | 20,000 lb / 10Ton with a servo-hydraulic cylinder |

Die-Cut Station Press Stroke | 4" / 100 mm |

Index Dial Size | 60" / 1525 mm |

Press Daylight | 2.750" / 70 mm (for overall die height) |

Type | Cartridge Heaters with TC embedded in the upper die mounting platen |

Controls | Temperature Controller or AB PLC with TC Module |

MAX Temp. | 450°C |

Utilities | 3 Phase 200-240 VAC 10A |

Model No. | TPRS-450 |

Press Type | Air-Over Hydraulic or Servo-Hydraulic cylinder with position feedback |

Max Press Force | 20,000lb / 10 Ton (metric) |

Utilities | Single Phase 200-240 VAC 20A |

Sankyo | Electric CAM Alfa Series High Precision Indexers |

Positions | 3, 4, 6 or 8 positions available as an option |

19AD | 72 - 96" Diameter |

23AD | 120" Diameter Dials |

Controls | ABB Variable Frequency Drive (VFD) |

Fast-Stop | Optional Break Resistor |

Electricity | 100-240 VAC / 60-70 A / 50-60 Hz |

Pneumatic | 80 PSI / 5 bar - Clean Dry Air (CDA) |

Process Controller | Allen Bradley PLC - Compact Logix |

Operator Interface | 12" Touch Screen PC HMI |

PC HMI Operating System | Windows 7 Pro |

Processor | Generation Intel® Core™ i7-8700 T with vPro™ 2.40 GHz |

Storage | 60-128 GB SSD |

Memory | 4GB DDR4 2666 MHz SoDIMM |

PC-HMI Ports & Slots | PC HMI / 2 x USB 3.1 Gen 2**l, 2 x USB 3.1 Gen 1**, RJ45 (1 Gb Ethernet), HDMI |

Rotary Heat Sealer | 103" x 96" x 87" / 262 cm x 244 cm x 220 cm |

Heat Sealing Station | 5500 lb / 2500 kg |

Indexing Dial | 175 lb / 79 kg |

Total Shipping Weight | 6000 lb / 2775 kg / Crated |

Temperature | 65-95°F / 18-35°C |

Humidity | 68% Maximum relative humidity non-condensing |

Elevation | up to 2000 m |

Machine Safety | ISO 13849-1 / OSHA |

Certifications | UL per Request |

Software | FDA 21 part 11 |

IQ | Documents available up on request for a fee |

FAI and DOE | Documents available up on request for a fee |

OQ | Support available at customer site per request |

Whatever you seal, hybrid is the best to control your process

Tuned Frequency

Calibrated RF Power

Easy Navigation, Friendly Validation

ONEX RF uses Allen Bradley PLC and 12" Touch Screen PC based HMI to control the RF Welding Process

The RF welding process is very easy to setup and validation because our RF generator technology output is always constant. Your validated parameters will allays be constant and never require tweaking even when the tube starts degrading. Read more about RF Welder's Process Control and RF Welder's theory of operations... We offer validation support, including FAT Installation Qualification (IQ) documentation.

For quick response, please provide details of your product, process needs, and full contact information.

For application related questions, you can always reach us by phone at +1(626)358-6639.

We offer excellent service:

We look forward to working with you soon.

EXPECT ONLY EXCELLENCE

ONEX RF Inc. is dedicated to giving you excellent service with quality results. Expect only excellence.

Copyright © 2020 ONEX RF . All rights reserved.Trademarks, including but not limited to ONEX RF Design are the trademarks or registered trademarks of ONEX RF and used under license by ONEX RF Based on mixed usage scenario.Terms of Use | Privacy Policy